Client success story

Recreational Vehicle Manufacturer

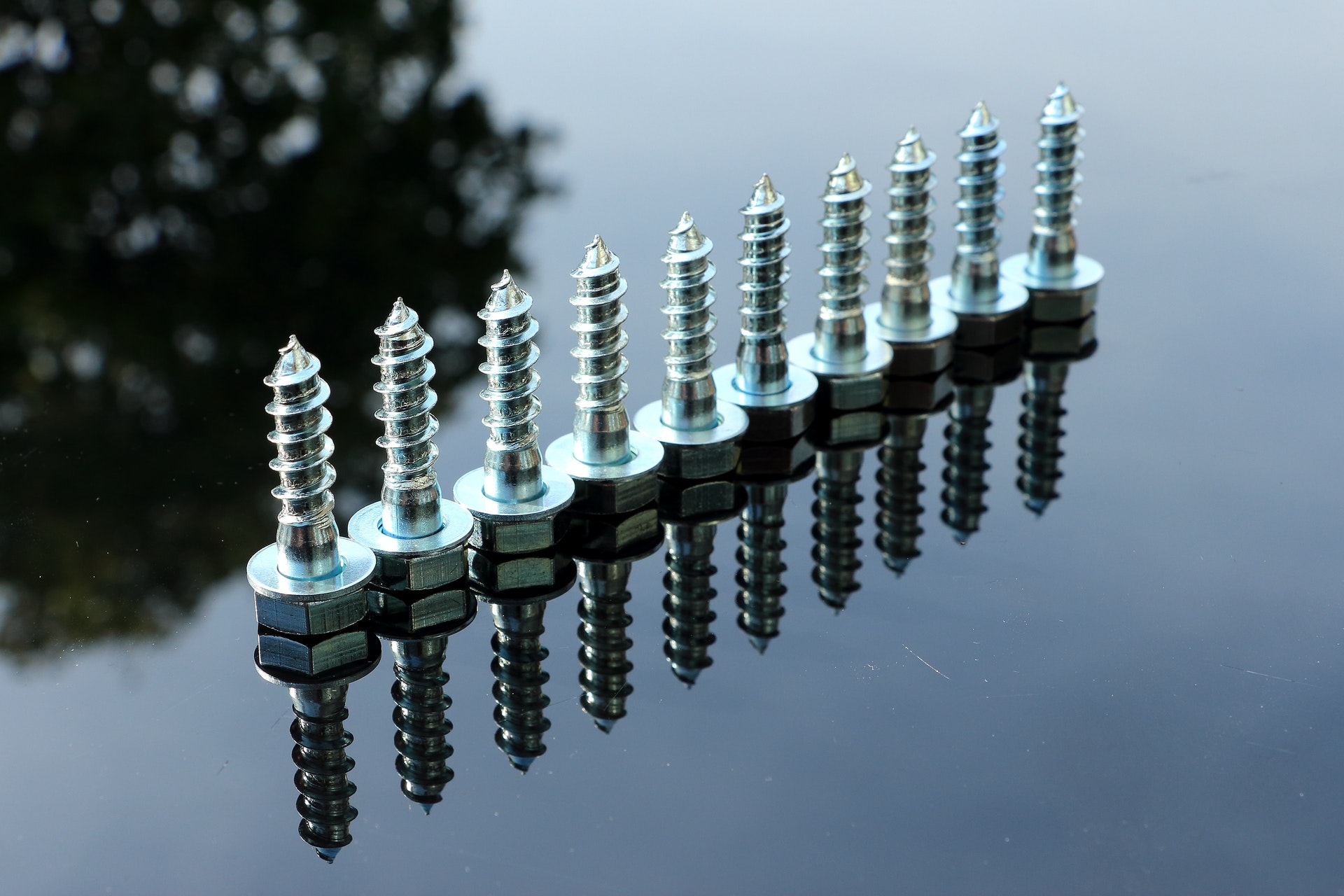

From securing the supply line for stainless steel fasteners to creating production cart sequences, a world-renowned recreational vehicle manufacturer has had a unique SBS Solution built and optimized during their 34-year relationship with SBS.

Client Bio

34 years

of relationship with SBS

12

Manufacturing Locations in 6 Countries

$5 bn

in Sales (USD)

13,000+

Employees Worldwide

Small Beginning

The client loses their supplier for stainless steel hardware. SBS is recommended by the current supplier to fill this need due to location, experience, and knowledge of international sourcing and distribution. SBS secures the supply line for stainless steel fasteners on one line in in 1986.

Phase 1:

- Source all hardware from quality manufacturing in low cost countries.

- Manage demand flow in client portal.

- Release weekly demand once per week.

- Ship to client warehouse for floor distribution.

1990

- Client begins their journey to become the premier supplier in their category.

- SBS opens a new location in Canada. Lead time reduced to less than 24 hours.

- Material is delivered directly to central store for consumption, reducing administrative costs of material handling C-Level parts.

1994

- SBS works with the client to install gravity feed racks on the production line. +15% Warehouse space is repurposed to production.

- Assembly personnel stay at workstation increasing production by +5%.

- Stocking levels are calculated using demand forecast/production rates.

1998

- Due to performance of gravity feed lines, SBS secures all lines in plant one.

- Resourcing parts to global manufacturing nets client +10% cost savings.

- Gravity feed conversion opens and additional +45% of warehouse space to production.

- Increased production on additional lines increases by +5% – 8%.

2001-2006

- Client sales continue to increase. Need for floor space currently used by gravity flow racks is required to expand production further.

- Client moves from batch to inline manufacturing.

- SBS collaborates with client to create production cart sequences that are delivered to the assembly line every 4 hours.

- Client gains JIT inventory with no residual inventory at the end of the day. Cash Flow increase.

- SBS internally works with global suppliers to creates prepackaged bins for supply chain flexibility and cost savings.

- Quality controls are put in place, and audited by the client, to eliminate quality inspection at the client. Admirative and material handling savings +12%.

- Client’s international supply base conforms price, quality, and service in all plants. Savings = Unmeasurable.

- SBS Engineering proposes and completes standardization project between platforms. Incremental savings +15%.

2008-2013

- All safety stock is removed from the client.

- Quality control and auditing is handed over to SBS.

- SBS opens 2 locations in Mexico and one in Europe to support additional plants with same system.

- Client instructs +50 vendors to work with SBS to establish Directed Source program. SBS is responsible for planning, purchasing, quality, and distribution of 80% of client direct parts.

- SBS bypasses receiving on all parts by uploading inventory every 4 hours. Equivalent of 4 full time employees (FTE).

- All parts are loaded to assembly straight line. Reducing material handling by 4 FTE. Reducing quality control by 3 FTE.

2017-2020

- SBS Engineering begins Value Analysis/Value Engineering project focused on cost reduction for directed source parts by qualifying Fit, Form, Function global equivalent products.

- SBS starts project with Austrian engine manufacture to reduce cost and increase standardization.

- Client acquires 3 new companies in the United States. SBS establishes teams and physical locations to support integration.

2021 and Beyond

- Client moving to one-piece flow for greater flexibility and customization.

- Build to order strategy with short turn around.

- Two hour inventory turns.

Read more

Recreational Vehicle Manufacturer

From securing the supply line for stainless steel fasteners to creating production cart sequences, a world-renowned recreational vehicle manufacturer has had a unique SBS Solution built and optimized during their 34-year relationship with SBS.

Robotics Manufacturer

Rapidly growing warehouse robotics manufacturer was experiencing long lead times, poor customer service, and high prices. SBS worked with our global partners to reduce cost, introduced responsive account management, and implemented an automated kanban to eliminate lead time concerns.

Semiconductor Industry Client

Lack of understanding of the clients process led to both exhausted and excess inventory. After an extensive analysis, a unique program with custom packaging, delivery by inventory technician, and redistribution of unused parts was set up.

Redesigning a part improved productivity

A failing part caused production delays and cost overruns in a precision assembly. SBS Engineering collaborated with the client to develop a part that eliminated the quality concerns and need for redundant inspections.